Here’s a structured overview of a manganese ore processing plant, covering key stages from mining to final product:

—

1. Mining & Extraction

- Methods: Open-pit or underground mining, depending on ore depth.

- Ore Types:

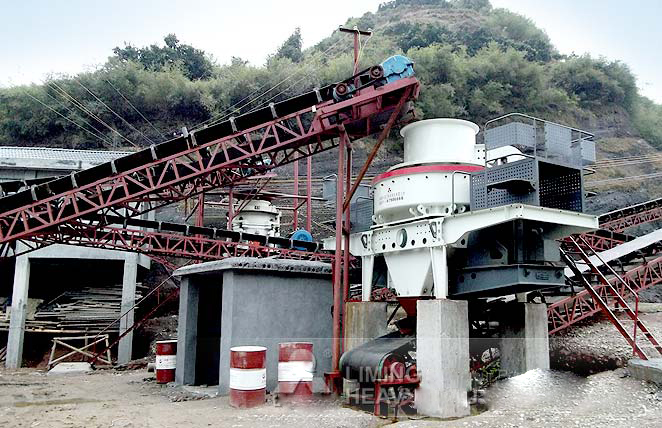

- Primary Crushing: Jaw crusher reduces large chunks to ~150mm.

- Secondary Crushing: Cone crusher further breaks down to ~25mm.

- Screening: Vibrating screens separate sizes for efficient processing.

- Used for coarse manganese particles (e.g., pyrolusite).

- Equipment: Jiggers, spiral concentrators.

- For magnetic ores (e.g., manganese carbonate).

- Low-intensity magnets remove iron; high-intensity separates Mn minerals.

- For fine-grained or complex ores.

- Chemicals: Collectors (fatty acids) float Mn minerals; depressants (starch) suppress impurities.

- Removes clay/silt adhering to ore (for weathered deposits).

- Leaching: Acid (H₂SO₄) dissolves Mn from low-grade ores.

- Electrowinning: Manganese sulfate solution is electrolyzed to produce pure Mn metal.

- Blast furnace/electric arc furnace reduces ore with coke/coal at high temps (~1200°C).

- Products:

- Waste slurry is stored in lined ponds; water recycled.

– High-grade (>35% Mn): Direct shipping possible.

– Low-grade (<10% Mn): Requires beneficiation.

—

2. Crushing & Screening

—

3. Beneficiation (Upgrading)

Gravity Separation

Magnetic Separation

Flotation

Washing & Scrubbing

—

4. Hydrometallurgical Processing (Optional)

—

5. Smelting (For Ferromanganese/Siliconanganese)

– Ferromanganese (~80% Mn, ~15% Fe).

– Siliconanganese (~65% Mn, ~20% Si).

—

Leave a Reply