A good quality stone crushing line that incorporates a used impact crusher can be an efficient and cost-effective solution for producing aggregates, especially if you’re working with a limited budget. Here’s what you need to consider:

Key Components of a Stone Crushing Line

1. Primary Crusher (Jaw Crusher or Gyratory Crusher) – Breaks down large rocks into smaller pieces (~6-12 inches).

2. Secondary Crusher (Impact Crusher or Cone Crusher) – Further reduces material size (~1-3 inches).

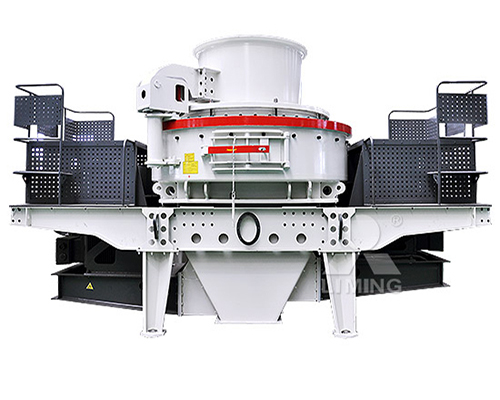

3. Tertiary Crusher (Vertical Shaft Impact Crusher – VSI) – Optional, for shaping fine aggregates.

4. Vibrating Screens – Separate crushed stones into different sizes.

5. Conveyor Belts – Transport material between stages.

6. Dust Suppression System – Reduces airborne particles.

Why Use a Used Impact Crusher?

✅ Cost Savings – Lower initial investment compared to new equipment.

✅ Quick Deployment – Faster setup if the machine is in good condition.

✅ Proven Performance – If well-maintained, used impact crushers can still deliver high-quality output.

What to Check When Buying a Used Impact Crusher

🔹 Wear Parts Condition (blow bars, aprons, liners)

🔹 Rotor Integrity (cracks or excessive wear)

🔹 Engine/Hydraulic System Health

🔹 Maintenance History & Service Records

🔹 Production Capacity Matches Your Needs

Best Applications for Impact Crushers

✔ Soft to medium-hard stone (limestone, dolomite)

✔ Recycling applications (concrete, asphalt)

✔ Producing cubical-shaped aggregates

Recommended Setup with Used Impact Crusher

1. [Primary Jaw Crusher] → [Used Secondary Impact Crusher] → [Screen] → [Final Product]

2. Optional: Add a tertiary VSI crusher for better shaping..jpg)

Top Brands for Used Impact Crushers

- Metso/Nordberg NP Series

- Sandvik CI Series

- Terex Pegson/Irock

- Hazemag AP Series

Would you like recommendations on where to source reliable used impact crushers? Or do you need help estimating production capacity? Let me know how I can assist further!

Leave a Reply