Grinding phosphate rock is a crucial step in the production of phosphate fertilizers, such as monoammonium phosphate (MAP) and diammonium phosphate (DAP). The process involves reducing the particle size of phosphate ore to improve reactivity in downstream chemical processing (e.g., sulfuric acid digestion). Here’s an overview of mills commonly used for grinding phosphate:

Types of Mills Used for Phosphate Grinding

1. Ball Mills

– Traditional and widely used for dry or wet grinding.

– Consist of rotating cylinders filled with steel balls that crush and grind the ore.

– Suitable for coarse to medium grinding (particle sizes ~100–300 µm).

2. Rod Mills

– Similar to ball mills but use long rods instead of balls for grinding.

– Produce a more uniform particle size with less fines, ideal for softer ores like phosphate.

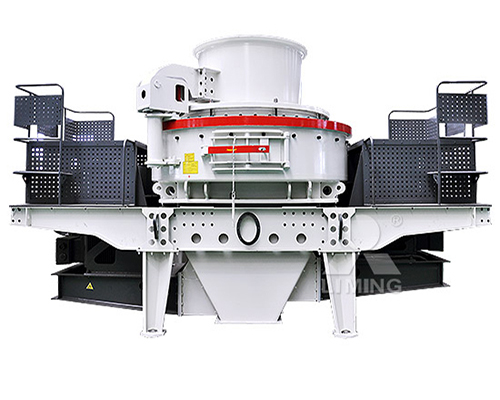

3. Vertical Roller Mills (VRM)

– Energy-efficient alternative to ball mills.

– Uses rollers to compress and grind phosphate against a rotating table.

– Better particle size control (~45–100 µm) and lower power consumption.

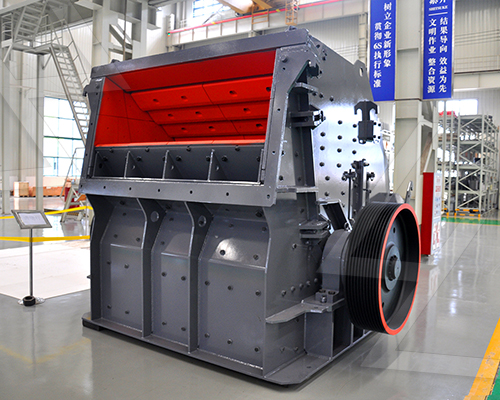

4. Hammer Mills & Impact Crushers

– Used for preliminary size reduction before fine grinding.

– Effective for breaking down larger chunks into smaller pieces (~1–5 mm).

5. High-Pressure Grinding Rolls (HPGR)

– Increasingly adopted for energy-efficient comminution.

– Compresses phosphate between two counter-rotating rollers under high pressure, reducing energy use by 20–30%.

6. Stirred Media Mills (Attrition Mills)

– Used for ultra-fine grinding (<20 µm) in specialized applications.

Key Considerations

- Moisture Content: Wet grinding (slurry) is common in phosphoric acid production, while dry grinding may be used for direct fertilizer applications.

- Energy Efficiency: VRMs and HPGRs offer significant energy savings over traditional ball mills (~30–50% less energy).

- Particle Size Requirements: Finer grinding improves acid digestion efficiency but increases energy costs—optimization is critical (~80% passing 75–150 µm typical).

- Abrasion: Phosphate rock can be abrasive, increasing wear on mill liners/media (requires hardened steel or ceramic liners).

- Dust Control: Dry milling requires dust suppression systems due to fine particulate generation.

Challenges

Would you like details on a specific milling process or optimization techniques?

Leave a Reply