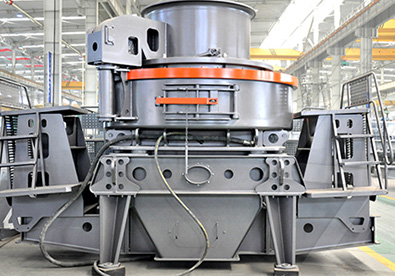

The Impact Crusher (with reference to 4340) likely refers to a crusher that utilizes impact forces to break materials, possibly incorporating AISI 4340 steel in its construction due to its high strength and toughness properties. Below is a breakdown of key aspects:

1. Impact Crusher Basics

– Function: Crushes materials by striking them with hammers/blow bars mounted on a rotating rotor.

– Applications: Used in mining, recycling, aggregates, and construction for crushing limestone, concrete, asphalt, and other medium-hard materials.

– Types: Horizontal Shaft Impactors (HSI) & Vertical Shaft Impactors (VSI).

2. Significance of “4340”

– Likely refers to AISI 4340 alloy steel, known for:

– High tensile strength (~745 MPa) and toughness.

– Excellent fatigue resistance (suitable for high-impact applications).

– Often used in crusher components like rotors, shafts, or blow bars.

3. Key Components Made from 4340 Steel

– Rotor: The core rotating part that withstands repeated impact loads.

– Blow Bars/Hammers: Replaceable wear parts that strike the material.

– Shafts: High-stress components requiring fatigue resistance.

4. Advantages of Using 4340 Steel

– Longer service life due to wear resistance.

– Reduced downtime from fractures/failures.

– Suitable for heavy-duty crushing operations.

5. Maintenance Considerations

– Regular inspection of blow bars/liners for wear.

– Balancing the rotor to prevent vibration-induced fatigue.

– Proper heat treatment (quenching & tempering) maximizes 4340 steel properties.

6. Popular Brands/Models Using High-Strength Alloys

Some manufacturers use advanced alloys like 4340 in their designs:

– Metso Nordberg® NP Series (HSI)

– Sandvik CI Series Impact Crushers

– Terex Pegson Horizontal Shaft Impactors

If you’re referring to a specific model (e.g., “Impact Crusher Model 4340”), check the manufacturer’s specifications for exact material details and performance metrics..jpg)

Would you like details on maintenance tips or alternatives to 4340 steel?

Leave a Reply