To achieve 300 mesh (approximately 50 microns) output from a rock crusher with a capacity of 100 tons per hour, you’ll need a multi-stage crushing and grinding setup. Here’s a breakdown of the process:

1. Primary Crushing (Jaw/Cone Crusher)

– Input: Large rocks (~12–24 inches).

– Output: 3–6 inches.

– Equipment: Jaw crusher or gyratory crusher.

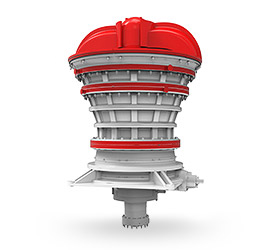

2. Secondary Crushing (Cone Crusher)

– Input: 3–6 inches.

– Output: 0.5–2 inches.

– Equipment: Cone crusher or impact crusher.

3. Tertiary Crushing (Vertical Shaft Impact Crusher or Fine Cone Crusher)

– Input: 0.5–2 inches.

– Output: 1/4 inch (~6 mm).

– Helps reduce load on grinding mills.

4. Grinding Mill for 300 Mesh Fineness

For ultra-fine grinding (~50 microns / 300 mesh), you’ll need:

# Option A: Ball Mill + Classifier

– Feed Size: ≤1/4 inch (~6 mm).

– Capacity: ~100 TPH (requires multiple mills).

– Closed-circuit with an air classifier to ensure proper sizing.

# Option B: Vertical Roller Mill (VRM)

– More energy-efficient than ball mills.

– Can handle up to ~100 TPH depending on hardness.

# Option C: Raymond Mill / Pendulum Roller Mill

– Best for softer materials (limestone, gypsum).

– Capacity per unit typically ≤20 TPH, so multiple units needed..jpg)

# Option D: High-Pressure Grinding Rolls (HPGR) + Ball Mill

– Energy-efficient pre-grinding before final milling.

5. Screening & Air Classification

– A high-efficiency air classifier ensures the final product meets the required fineness (300 mesh).

Estimated Power & Cost Considerations:

– Total power requirement: ~500–1,000 kW (depends on rock hardness).

– Wear parts cost will be significant due to abrasion at fine grinding levels.

Would you like recommendations based on specific rock types (granite, limestone, basalt, etc.)? Or do you need help selecting vendors/manufacturers?

Leave a Reply