Crushing equipment and sand screening machines are essential components in industries like mining, construction, and aggregate production. Here’s an overview of both:

1. Crushing Equipment

1. Crushing Equipment

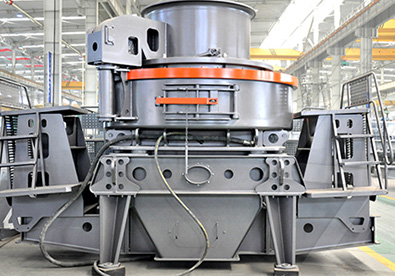

Crushing machines break down large rocks, stones, or minerals into smaller sizes for further processing or direct use.

# Common Types of Crushing Equipment:

– Jaw Crusher: Primary crusher for coarse crushing (e.g., granite, basalt).

– Cone Crusher: Secondary/tertiary crushing for finer output (e.g., limestone, iron ore).

– Impact Crusher: Uses impact force for softer materials (e.g., recycled concrete, asphalt).

– Gyratory Crusher: High-capacity primary crushing (used in large mining operations).

– Roll Crusher: Compression-based crushing for coal and softer ores.

– Hammer Mill: High-speed impact crusher for brittle materials.

# Applications:

✔ Quarrying & Mining ✔ Construction aggregates ✔ Recycling demolition waste

—

2. Sand Screening Machine

Sand screening machines separate particles by size to ensure uniformity in sand quality.

# Common Types of Sand Screening Machines:

# Common Types of Sand Screening Machines:

– Vibrating Screen: Most common; uses vibration to classify sand into different sizes.

– Rotary Trommel Screen: Drum-based screening ideal for wet/dry materials.

– Linear Motion Screen: Horizontal vibration for fine screening applications.

– High-Frequency Screen: Efficient separation of ultra-fine particles (<3mm).

# Applications:

✔ Sand washing plants ✔ Concrete production ✔ Road construction

—

Key Considerations When Choosing Equipment:

1. Material Hardness → Determines crusher type (jaw vs. impact).

2. Desired Output Size → Fine vs. coarse crushing/screening needs.

3. Capacity Requirements → Tons per hour (TPH) dictates machine size.

4. Mobility → Stationary vs. portable (wheeled/track-mounted units).

Would you like recommendations based on a specific application?

Leave a Reply