A rock crusher and hydraulic cyclone are key components in the processing of bauxite, the primary ore for aluminum production. Below is an explanation of their roles and how they integrate into bauxite processing:

1. Rock Crusher for Bauxite

1. Rock Crusher for Bauxite

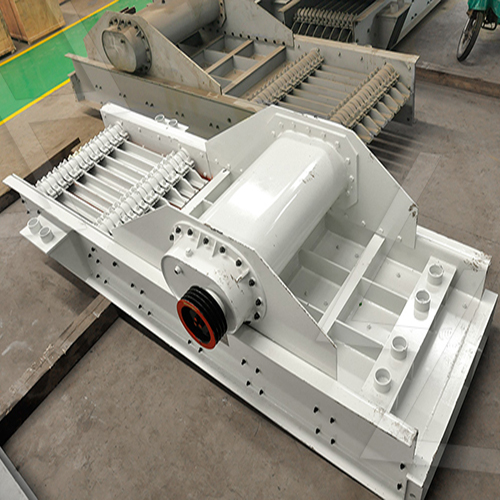

– Purpose: Reduces raw bauxite ore into smaller particles for further processing.

– Types Used:

– Jaw Crusher: Primary crushing to break large chunks (~1m) into smaller pieces (~150mm).

– Cone Crusher/Gyratory Crusher: Secondary crushing to reduce size further (~20–30mm).

– Impact Crusher: Sometimes used for softer bauxite ores.

– Key Considerations:

– Bauxite is relatively soft (Mohs hardness 1–3), so crushers must minimize fines generation (excessive fines can hinder later stages).

– Dust control is critical due to bauxite’s powdery nature.

2. Hydraulic Cyclone (Hydrocyclone)

– Purpose: Classifies crushed bauxite slurry by particle size/density, separating coarse and fine particles.

– Role in Bauxite Processing:

– After crushing, bauxite is mixed with water to form slurry.

– Hydrocyclones separate:

– Coarse particles (underflow): Sent for grinding or digestion.

– Fine particles (overflow): Further processed or treated chemically (Bayer Process).

– Advantages:

– No moving parts, low maintenance.

– Efficient separation at high throughputs.

3. Integration in Bauxite Processing Flow

1. Crushing: Raw bauxite → Jaw crusher → Cone crusher → Output (~20mm).

2. Slurry Preparation: Crushed ore mixed with water.

3. Classification: Slurry pumped into hydrocyclones to separate coarse/fine fractions.

4. Digestion: Coarse fraction may be ground further before Bayer Process digestion.

Key Equipment Suppliers

Key Equipment Suppliers

– Rock Crushers: Metso, Sandvik, Terex, ThyssenKrupp.

– Hydrocyclones: Weir Minerals, Multotec, FLSmidth Krebs.

Would you like details on specific configurations or operational challenges?

Leave a Reply