Mineral processing of iron involves several steps to extract iron from its ores and prepare it for use in steelmaking or other applications. The main stages include crushing, grinding, beneficiation, and pelletizing/sintering. Below is a detailed breakdown:

1. Crushing & Grinding

1. Crushing & Grinding

– Purpose: Reduce the size of iron ore (hematite, magnetite, etc.) for efficient beneficiation.

– Methods:

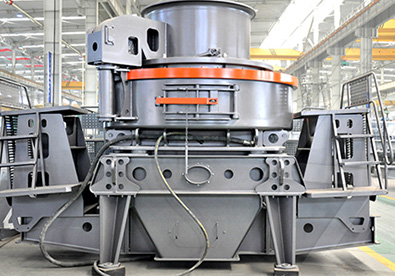

– Primary crushing (jaw crushers, gyratory crushers).

– Secondary crushing (cone crushers).

– Grinding (ball  ls, rod mills) to produce fine particles (~45–150 microns).

ls, rod mills) to produce fine particles (~45–150 microns).

2. Beneficiation (Ore Dressing)

– Goal: Increase iron content by removing impurities (silica, alumina, phosphorus).

– Techniques:

# (a) Magnetic Separation

– Used for magnetite (Fe₃O₄), which is naturally magnetic.

– Low-intensity magnetic separators (LIMS) remove gangue minerals.

– High-intensity magnetic separators (HIMS) refine concentrate.

# (b) Gravity Separation

– Uses density differences to separate hematite/goethite from gangue.

– Methods: Spiral concentrators, jigs, shaking tables.

# (c) Froth Flotation

– Used for finely disseminated ores or those with silica/alumina impurities.

– Collectors attach to iron particles while depressants suppress gangue.

# (d) Wet Processing & Scrubbing

– Removes clay and soft contaminants via washing/screening.

3. Dewatering & Tailings Management

– Thickeners and filters remove water from concentrate.

– Tailings (waste material) are stored safely in ponds or reprocessed.

4. Agglomeration (Pelletizing/Sintering)

Iron ore fines must be agglomerated before smelting:

– Pelletizing:

Fines are mixed with binders (bentonite), rolled into pellets (~8–16 mm), and fired (~1200–1350°C).

– Sintering:

Fine ore is blended with coke breeze/fluxes and heated (~1300°C) to form porous lumps for blast furnaces.

5. Final Product Specifications

High-grade iron ore typically contains:

– Fe: >62%

– SiO

Leave a Reply