A pulverizing plant for quartz is a facility designed to crush, grind, and process quartz into fine powders or granules for various industrial applications. Quartz, a hard and abrasive mineral (Mohs hardness of 7), requires specialized equipment for efficient size reduction.

Key Components of a Quartz Pulverizing Plant

Key Components of a Quartz Pulverizing Plant

1. Primary Crusher

– Jaw crusher or gyratory crusher breaks large quartz rocks into smaller pieces (~25–100 mm).

2. Secondary Crushing

– Cone crusher or impact crusher further reduces quartz to finer sizes (~5–20 mm).

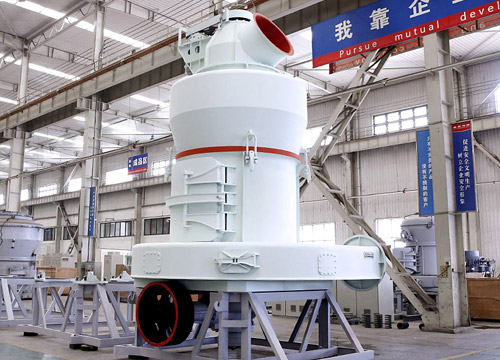

3. Grinding Mill (Pulverizing Stage)

– Ball Mill: Uses steel balls to grind quartz into fine powder (45–150 microns).

– Raymond Mill: Produces medium-fine powder (80–325 mesh).

– Vertical Roller Mill (VRM): Energy-efficient grinding for ultra-fine powders (<45 microns).

– Hammer Mill: Suitable for coarse to medium grinding (~200–500 microns).

4. Classification System

– Air classifiers or vibrating screens separate particles by size.

5. Dust Collection & Pollution Control

– Bag filters, cyclones, and electrostatic precipitators capture fine silica dust (critical due to silicosis risks).

6. Packaging & Storage

– Silo storage and automated bagging systems for finished quartz powder.

Applications of Pulverized Quartz

Applications of Pulverized Quartz

– Glass manufacturing

– Ceramics & refractories

– Foundry sand (silica sand)

– Electronics (semiconductor industry)

– Construction materials (cement, paints, coatings)

Challenges in Quartz Pulverization

– High abrasiveness → Wear-resistant linings/materials required.

– Silica dust hazards → Strict OSHA/MSHA regulations.

– Energy consumption → Optimized grinding circuits reduce costs.

Would you like details on specific machinery or process optimization techniques?

Leave a Reply