A TPH (Tonnes Per Hour) gold processing plant is designed to extract gold from ore at a specific throughput rate. The design and equipment selection depend on factors like ore type, gold grade, recovery method, and environmental considerations. Below is a general outline of key components and processes for a typical gold processing plant:

—

1. Plant Capacity & Ore Characteristics

– Throughput: e.g., 50 TPH, 100 TPH, 300 TPH (customizable).

– Ore Type: Hard rock (lode gold), alluvial/placer, or refractory ore.

– Gold Grade: Grams per tonne (g/t) or ounces per tonne (oz/t).

– Gangue Minerals: Presence of sulfides, quartz, or clay affecting processing.

—

2. Key Processing Stages

# (A) Crushing & Grinding

– Primary Crushing: Jaw crusher or gyratory crusher (for hard rock).

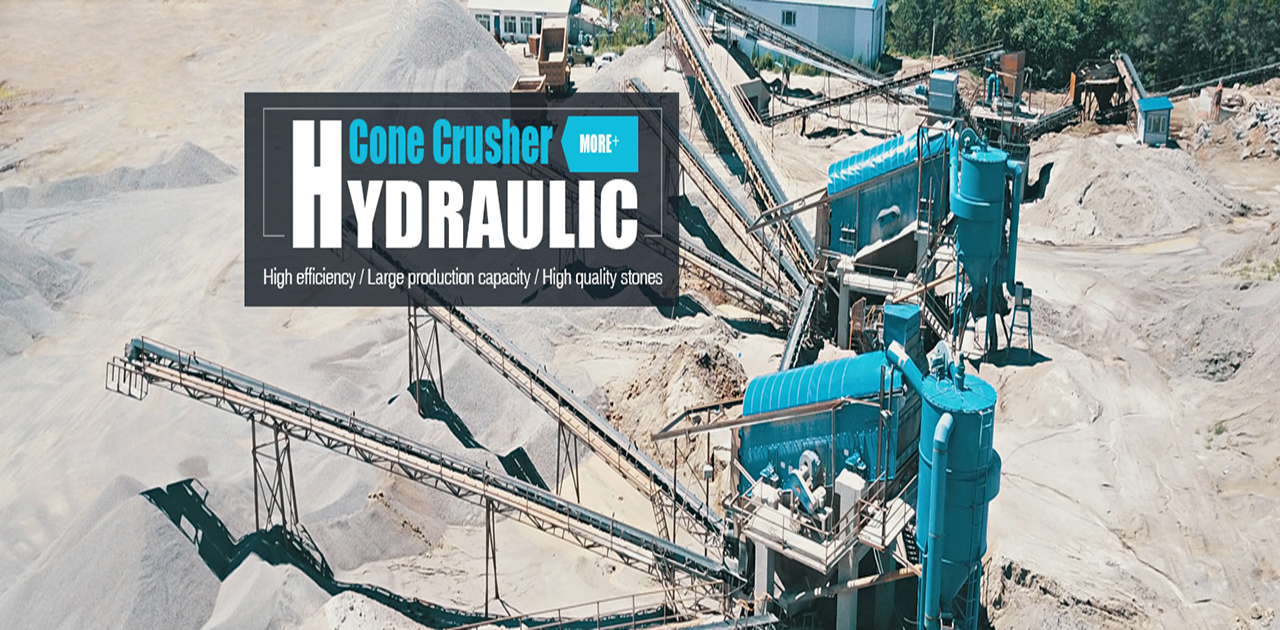

– Secondary/Tertiary Crushing: Cone crusher or impact crusher.

– Grinding: Ball mill, rod mill, or SAG mill to achieve fine particle size (e.g., 75 microns for leaching).

# (B) Gravity Separation (Optional)

– For free-milling gold: Shaking tables, centrifugal concentrators (e.g., Knelson/Falcon), jigs.

– Recovers coarse gold before leaching.

.jpg) # (C) Leaching & Adsorption

# (C) Leaching & Adsorption

– CIL (Carbon-in-Leach) / CIP (Carbon-in-Pulp):

– Ore slurry mixed with cyanide (NaCN/KCN) to dissolve gold.

– Activated carbon absorbs gold from solution.

– Electrowinning recovers gold from loaded carbon.

– Heap Leaching (for low-grade ores): Ore stacked on pads and irrigated with cyanide.

# (D) Flotation (For Sulfide Ores)

– Froth flotation to concentrate sulfide minerals before leaching.

# (E) Refining

# (E) Refining

– Smelting of electrowinning sludge to produce doré bars (~90% purity).

– Further refining via aqua regia or Miller process for 99.99% purity.

—

3. Equipment List (Example for 100 TPH Plant)

| Stage | Equipment |

|—————-|———————————-|

| Crushing | Jaw crusher, cone crusher |

| Grinding

Leave a Reply