# Mini Cement Plant Project Report

## 1. Introduction

A mini cement plant is a small-scale cement production facility with a capacity ranging from 50 to 200 tonnes per day (TPD). These plants are cost-effective, require less investment, and are ideal for rural and semi-urban areas. This report provides a detailed analysis of setting up a mini cement plant, including market potential, technical requirements, financial aspects, and regulatory compliance.

—

## 2. Market Potential & Demand

– The global demand for cement is rising due to urbanization and infrastructure development.

– Mini cement plants cater to local demand, reducing transportation costs.

– Ideal for regions with limited access to large cement manufacturers.

– Growing demand in construction, housing, roads, and small-scale industries.

Target Market:

– Local construction companies

– Government infrastructure projects

– Individual home builders

– Small-scale contractors

—

## 3. Technical Details & Manufacturing Process

A) Raw Materials Required:

1. Limestone (main raw material)

2. Clay/Shale (for silica & alumina)

3. Gypsum (for setting time control)

4. Coal/Pet coke (fuel for kiln)

5. Iron ore/Bauxite (for iron & aluminum oxides)

B) Production Process:

B) Production Process:

1. Crushing & Grinding: Limestone and clay are crushed into fine powder.

2. Mixing & Blending: Raw materials are mixed in correct proportions.

3. Preheating & Calcination: Heated in a rotary kiln (~1450°C) to form clinker.

4. Cooling & Grinding: Clinker is cooled and ground with gypsum to form cement.

5. Pa.jpg) ng & Dispatch: Cement is packed in bags (50 kg) for distribution.

ng & Dispatch: Cement is packed in bags (50 kg) for distribution.

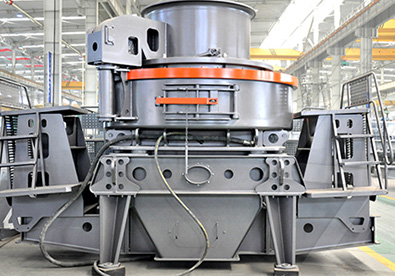

C) Machinery & Equipment:

| Equipment | Purpose |

|———–|———|

| Crusher | Crushing raw materials |

| Ball Mill/Roller Mill | Grinding raw mix |

| Rotary Kiln | Clinker production |

| Cooler | Cooling clinker |

| Cement Mill | Final grinding of clinker + gypsum |

| Packing Machine | Bagging cement |

—

## 4. Project Cost Estimation (50 TPD Plant)

| Component | Estimated Cost (INR) |

|———–|———————|

| Land & Site Development | ₹50 – ₹100 lakhs |

| Machinery & Equipment | ₹3 – ₹5 crores |

|

Leave a Reply