A portable ball mill for processing magnetite iron ore is a practical solution for small-scale mining operations or remote locations where mobility and flexibility are essential. Here’s a breakdown of the key considerations for such a setup:

1. Magnetite Iron Ore Characteristics

– High Density & Hardness: Magnetite (Fe₃O₄) is dense (5.2 g/cm³) and often requires fine grinding to liberate iron from gangue minerals.

– Magnetic Properties: Beneficiation typically involves magnetic separation after grinding.

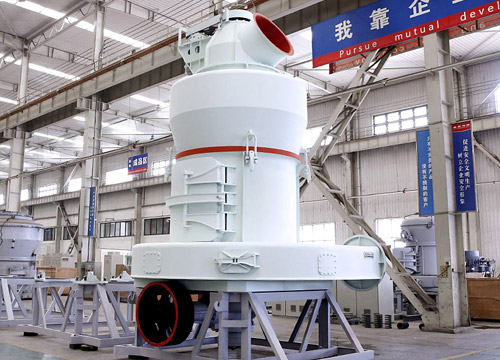

2. Portable Ball Mill Design Considerations

– Compact & Mobile: Must be trailer-mounted or skid-based for easy transport.

– Power Source: Diesel engine or electric motor (if grid power is available).

– Grinding Media: Steel balls (chrome or forged) to handle magnetite’s hardness.

– Feed Size: Ideally ≤25mm (may require pre-crushing with a portable jaw crusher).

– Discharge Size: Target 75–150 microns for effective downstream magnetic separation.

3. Typical Specifications for Portable Ball Mill

| Parameter | Specification |

|——————–|————–|

| Capacity | 1–10 TPH (varies with ore hardness) |

| Mill Dimensions | ~2m x 3m (portable designs) |

| Motor Power | 15–75 kW (depends on throughput) |

| Rotation Speed | 70–80% of critical speed |

| Liner Material | High manganese steel/rubber |

4. Supporting Equipment

– Pre-Crushing Unit: Portable jaw/cone crusher to reduce feed size.

– Screening System: Vibrating screen to control feed size.

– Magnetic Separator: Wet/dry drum separator to recover magnetite post-grinding.

– Classifier (Optional): Spiral classifier or hydrocyclone for closed-circuit grinding.

5. Challenges & Solutions

5. Challenges & Solutions

– Abrasion Wear: Use high-chrome grinding media and replaceable liners.

– Energy Consumption: Optimize ball charge and mill speed.

– Moisture Content: Dry grinding preferred; wet milling requires slurry handling.

6. Suppliers of Portable Ball Mills

6. Suppliers of Portable Ball Mills

Companies like:

– [Metso Outotec](https://www.mogroup

Leave a Reply