It looks like you’re referring to rock crushers used in industries such as mining, construction, and aggregate production. Here’s a breakdown of key aspects related to rock crushers in industrial applications:

Types of Rock Crushers

Types of Rock Crushers

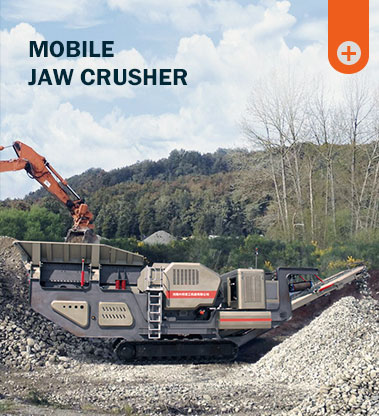

1. Jaw Crushers

– Primary crushing for hard, abrasive materials (e.g., granite, basalt).

– Uses compressive force to break large rocks into smaller pieces.

2. Cone Crushers

– Secondary/tertiary crushing for finer output.

– Ideal for medium-hard to hard rocks (e.g., limestone, quartz).

3. Impact Crushers (HSI/VSI)

– High-speed impact crushing for softer rocks (e.g., limestone, recycled concrete).

– Vertical Shaft Impactors (VSI) produce cubical aggregates for asphalt and concrete.

4. Gyratory Crushers

– Used in large-scale mining operations for high-capacity primary crushing.

5. Roll Crushers & Hammer Mills  – For softer materials like coal or overburden in mining.

– For softer materials like coal or overburden in mining.

Key Industries Using Rock Crushers

– Mining: Crushing ore for mineral extraction (gold, copper, iron).

– Construction: Producing aggregates (gravel, sand) for concrete and road base.

– Quarrying: Processing crushed stone for landscaping and building materials.

– Recycling: Crushing concrete, asphalt, and demolition waste for reuse.

Leading Manufacturers

– Metso Outotec

– Sandvik

– Terex (including Powerscreen & Finlay)

– Eagle Crusher

– McCloskey International

Would you like details on specific crusher models, applications, or maintenance tips? Let me know how I can assist further!

Leave a Reply